|

| April 22, 2014 | Volume 10 Issue 16 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

Freudenberg puts FEA seal of approval on wind turbine gasket

Simulia's Abaqus and Isight solutions determine robust design for wind turbine component.

The wind has long been used as a metaphor for constant change, wayward and capricious. Wind turbine engineers deal with that changeability every day along with a host of other challenging factors. Their products must operate in desert sandstorms and in corrosive salt water. The ambient temperature at the turbine site can be blisteringly high or numbingly frigid. And the loads on the gaskets and slewing bearings can vary as the wind changes direction and the nacelle and blades swing around.

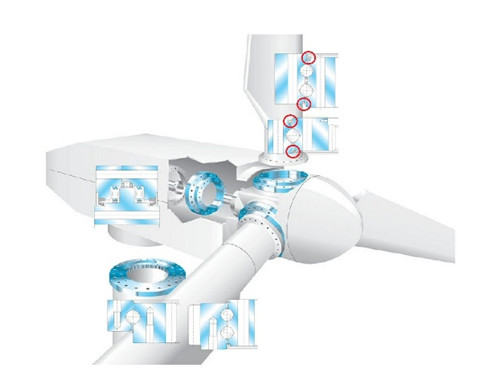

Through all these conditions, the gaskets must maintain a tight seal to protect the bearings. Every wind turbine contains at least four slewing bearings -- one for each rotor blade and a fourth for the yaw bearing (on which the nacelle rests and rotates) -- and each bearing contains two gaskets. "In a 3-MW turbine there are about 75 m of this type of gasket sealing device, every millimeter critical to performance," says Frank Schoenberg of Freudenberg Group, a German company that (among other technologies) develops and manufactures seals (Fig. 1).

Fig. 1. Shown is a wind turbine nacelle cutaway with bearings colored in blue and sealing solutions (gaskets) colored in red.

In addition to temperature and physical load variations, gasket seals can malfunction as a result of manufacturing processes. "Small imperfections created during manufacturing are inevitable," says Schoenberg, "and even small changes during elastomer production can significantly alter sealing gasket characteristics, such as Shore hardness [a standard measure of material hardness]."

Manufacturing tolerance variation and other load conditions can also cause deformation of the bearing, changing the width of the gap between the inner and outer bearing rings. Another deformation and tolerance problem can arise from the two rings having an axial offset (not being perfectly centered). Depending on the coefficient of friction of the gasket, this can have a large effect on the sealing function.

So, how are gaskets designed to ensure long-term performance? The goal is shifted from creating an optimal part -- one that performs excellently under a very limited set of nominal conditions -- to making a robust one that works acceptably under a wider, pre-specified range of circumstances.

"Robust designs are what I call 'satisficing,'" Schoenberg says. "They satisfy operating requirements and, as for their quality, they'll suffice."

In a study undertaken by Freudenberg to arrive at robust gasket design, Schoenberg and others used Abaqus finite element analysis (FEA) software and Isight optimization software -- both from SIMULIA, the Dassault Systemes 3DEXPERIENCE application. These tools enabled the analysts to simulate hundreds of variations and establish which was the most robust.

The road to robust

Implementing robust design involves a series of tradeoffs. How rigid must the gasket be to maintain shape under its load? How elastic must it be to keep a firm contact with the lubricating grease? Does it balance friction reduction and sealing function?

Maintenance and everyday performance are a tradeoff as well: The gasket should be easy to install and mount, but remain firmly fixed in place during operation. Finally, of course, there is the inevitable conflict between controlling cost and maximizing functionality. "The basic idea is that every decision is a sort of gamble," Schoenberg says. "It takes a risk for the sake of a probable gain, and you determine the size and likelihood of both."

The engineers had no shortage of variables to consider. The gasket in question is a continuously extruded contact seal made of an elastomer with proprietary properties. Its principal task is to protect the slewing bearing from the outside environment and seal the lubricating grease inside. Its diameter can be from 1 m to 5 m, but a typical cross-section is only 25 mm x 25 mm (a little under an inch square).

Durability requirements are stringent -- the gasket is expected to perform for 20 years, even in highly demanding environments. The design is constantly being updated to reflect changing customer specifications or new deployment locations for wind turbines. Under normal operation, the part has to perform under both positive pressure and the vacuum from within the bearing.

To meet field requirements, engineers must consider the pressure loading from the grease, friction torque, and de-mounting force, all while hitting production cost targets. Designs are evaluated using physical prototyping and simulations.

"For time and development cost considerations," Schoenberg says, "most physical testing and simulations are related to performance under nominal conditions." However, manufacturing results, and field circumstances, have a way of shifting. To be a truly robust design, the gasket should perform well even under variations from the nominal. Multiple analyses reflecting changing loads and conditions were clearly needed as well.

Simulating a real-world problem, finding a robust solution

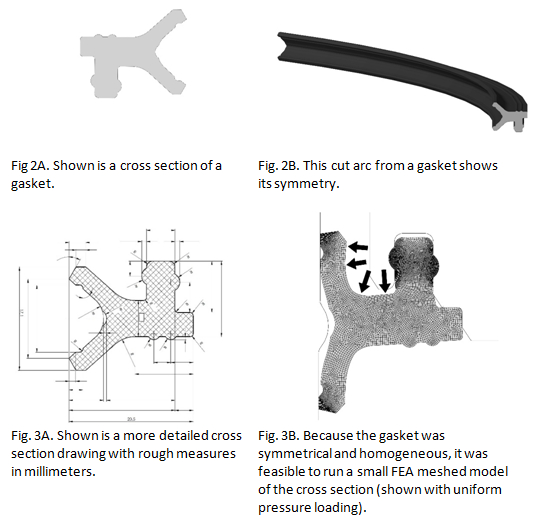

The first task of the analysis was creating a meshed model to run in Abaqus. Setting up its characteristics was straightforward: The bearing, which is metal, was defined as inflexible compared to the elastomer gasket, which had nonlinear properties. Because the gasket was made from homogeneous material and symmetric, it was possible to model and mesh a 2D cross-section of it, greatly reducing run times while still achieving accurate results (Figs. 2A and 2B, 3A and 3B).

"Every model, and therefore every simulation, is a reduction of complexity of a real-world problem," Schoenberg says. "So long as your underlying assumptions are accurate, you can simplify quite a bit."

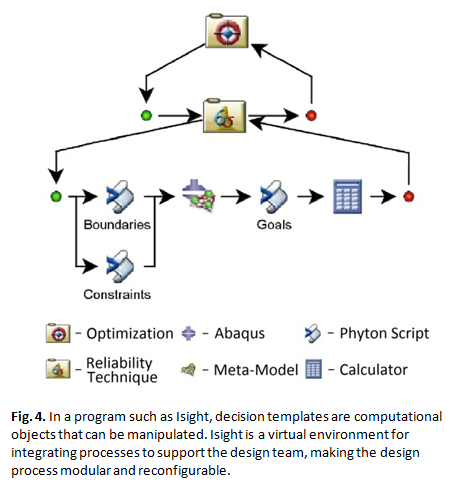

With the FEA model in hand, the engineers were ready to establish guidelines for optimization with Isight to home in on the variables that most significantly influence gasket performance. The engineers considered field test data, talked with expert product designers and material developers, and studied the geometry of previous wind turbine designs to ensure producibility. Eventually, the analysts selected 14 parameters to include in the optimization (including geometric parameters and material properties, such as hardness).

In the Isight workflow, Design of Experiment (DOE) methods were applied to iterations of FEA models to identify which of the parameters had the greatest effects on performance. This initial screening winnowed down the number of parameters under consideration to six crucial ones.

For the next phase of analysis, the Optimal Latin Hypercube method in Isight was used, running a total of 200 experiments that parametrically tailored geometrical dimensions and material properties (the six variables). "By identifying main effects, we could eliminate unimportant factors," Schoenberg says, "and concentrate our efforts where they would most affect the outcome." (Fig. 4)

The resulting robust design is not a one-size-fits-all solution by any means, Schoenberg says: "In this case study, we assumed one customer demand with different priority scenarios." For instance, one of the scenarios was defined by a high priority on pressure resistance and low priority on cost, with friction and mounting force of medium priority. A different customer demand might require significant modification. For example, the gaskets are made from only one elastomer, but it comes in different Shore hardnesses, resulting in about 20 distinct sub-materials.

"In this particular case, we ended up choosing a material with a high Shore hardness," Schoenberg says, "and we opted for geometric variables that would help to stiffen the inner sealing lip."

"Satisficing" results in far less time

Freudenberg's systematic approach to exploring robust design concepts yielded good results. "We finalized a gasket with characteristics superior to those achieved with more standard methodologies," says Schoenberg, "and it's less sensitive to processing and manufacturing imperfections, as well as to operating conditions for the wind turbine." The new part performs well under nominal conditions (as verified by physical prototyping), but it also performs well despite the "noise," such as tolerances and other uncertainties, that inevitably influence the operations of slewing bearings in the field.

"Our design approach not only improved our product," Schoenberg says, "it reduced computational run times, cutting costs significantly." The setup of the analyses took time, but running them with Isight shortened the optimization considerably. Compared to Freudenberg's former methodology, running time for each iteration was reduced from 30 min to only 0.1 sec. Computational times plummeted from an estimated 16,300 hr (about 678 days) to 100 hr (just over four days).

"We got good results, made better-informed decisions, and increased our efficiency," Schoenberg says. "We also established a meta-model that can be a starting point for cost-effective customization when a customer comes in with new demands and priorities."

In future research, Freudenberg will concentrate on, among other things, including more variables concerning various material scales and system levels. This will provide the engineers with greater design freedom. Subsequent analyses will integrate sealing components with bearing and wind turbine models to better explore system-level tradeoffs.

"Abaqus is the standard FEA solver here at Freudenberg," Schoenberg says. "SIMULIA's FEA and optimization tools work well together."

Source: Dassault Systemes, SIMULIA

Published April 2014

Rate this article

View our terms of use and privacy policy